Special Annealing Magnetic Circuit

-

While an exceptional vibration system is essential for a high-performance MC cartridge, we emphasise the critical role of the magnetic circuit. The cartridge's output signal is intricately tied to the movement of the vibration system within the magnetic circuit, where electricity is generated as the coil vibrates amidst the magnetic flux.

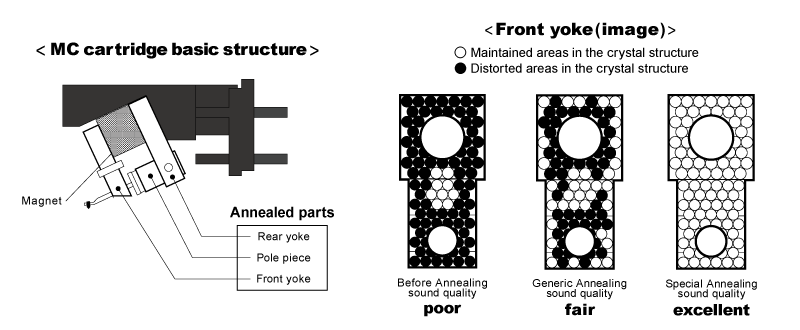

To ensure optimal output, it is imperative that the magnetic flux maintains high density and stability. We employ pure iron for our magnetic circuit due to its high magnetic permeability and exceptional stability, resulting in a distortion-free output. However, the processing of metal parts often distorts the crystal structure at the atomic level, leading to a loss of magnetic permeability.

-

Magnetic annealing, a process of heating and cooling processed parts, is crucial for restoring the distorted metal crystal structure and regenerating magnetic permeability. However, a generic magnetic annealing cannot fully restore distortions in the crystal structure. The magnetic annealing conditions vary depending on the parts material, size, shape, etc.

Our recent development focused on finding the best magnetic annealing process, including temperature, environment, duration, and heating and cooling rates. This meticulous approach has enabled us to unleash the full potential of pure iron's unique magnetic performance.

Magnetic annealing, a process of heating and cooling processed parts, is crucial for restoring the distorted metal crystal structure and regenerating magnetic permeability. However, a generic magnetic annealing cannot fully restore distortions in the crystal structure. The magnetic annealing conditions vary depending on the parts material, size, shape, etc.

Our recent development focused on finding the best magnetic annealing process, including temperature, environment, duration, and heating and cooling rates. This meticulous approach has enabled us to unleash the full potential of pure iron's unique magnetic performance. -

The new magnetic circuit has significantly enhanced sound quality, delivering unrivalled resolution, smooth wide-range expression, and expansive sound field. Experience the natural and dynamic sound of the Dynavector 20X2A cartridge, where an exceptional vibration system harmonises seamlessly with an optimised magnetic circuit.

Benefits of Magnetic Annealing

-

Magnetic annealing rejuvenates the distorted crystal structure, restoring magnetic permeability to its original state.

What is Annealing

-

Many people are probably familiar with "quenching," a heat treatment process commonly used on metal such as iron. Quenching strengthens and hardens metal by heating metal to a certain temperature then rapidly cooling it. This process is effectively used to make blades such as knives and scissors.

Many people are probably familiar with "quenching," a heat treatment process commonly used on metal such as iron. Quenching strengthens and hardens metal by heating metal to a certain temperature then rapidly cooling it. This process is effectively used to make blades such as knives and scissors.

On the other hand, not much is known about "Annealing", which is a heat treatment opposite to "Quenching". Differing to "quenching", the purpose of "annealing" is to soften metal by gradually cooling down the metal such as iron from a certain temperature.You may be wondering, "what's the point of making metal softer=weaker?", but this is not the case. Softened metal doesn't necessarily mean it is weak. While hardened metal may be resistant to wear and distortion it is also prone to chipping and breaking. Rather than simply hardening the metal, annealing aims to obtain strength by combining both hardness and flexibility. This is a traditional method requiring advanced skills that were also used by Japanese Samurai swordsmiths.

-

Annealing has an important role other than softening metal. It also restores the original performance of the metal by removing the distortion and internal pressure caused during processing and manufacturing of the material. With the appropriate annealing process the reborn metal is homogenous and can unleash its original properties to its full potential.

Annealing has an important role other than softening metal. It also restores the original performance of the metal by removing the distortion and internal pressure caused during processing and manufacturing of the material. With the appropriate annealing process the reborn metal is homogenous and can unleash its original properties to its full potential. -

Within "Annealing", "Magnetic Annealing" is a specialized heating treatment that focuses on improving the performance of magnetic materials. "Magnetic Annealing", improves the coercive force and magnetic permeability that determines the performance of magnetic circuits, and requires precise management of the heating temperature and atmosphere (the gas in the heat treatment furnace) according to the composition and characteristics of each metal material, making it a highly specialized type of heating treatment.

Dynavector has developed new magnetic annealing technology together with magnetic annealing specialists who are also involved in the development of the latest special materials and have successfully realized a new special annealing process to improve the performance of pure iron which is an excellent magnetic material.